Creating Cost-Effective, Efficient, and Reliable Energy Distribution

Sub-surface utility networks play a critical role in delivering essential services to various types of facilities and infrastructures. In urban environments, sub-surface utility networks support densely populated areas by providing critical infrastructure for heating and cooling. On campuses, these networks facilitate centralized energy distribution, making them cost-effective and efficient for educational institutions or corporate facilities. In industrial plants, utility networks are essential for maintaining operational efficiency and ensuring compliance with safety and regulatory standards.

Key systems supported by sub-surface utility networks include:

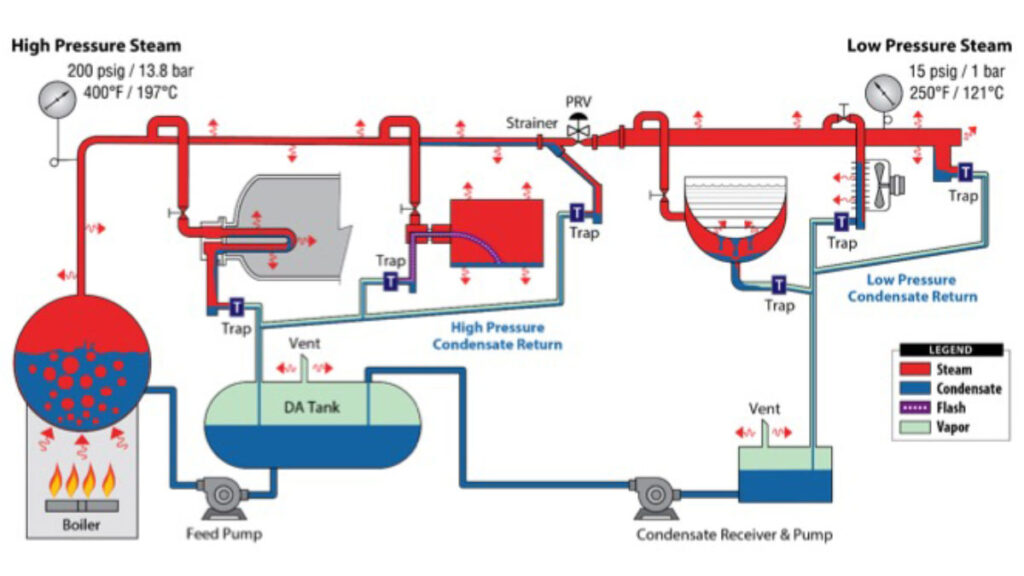

- Steam: Used for heating, energy transfer, and various industrial processes.

- Chilled Water: Distributed for cooling applications in buildings and processes.

- Fire Protection: Essential for ensuring safety and compliance in buildings and facilities.

Steam Basics

Steam is a widely used energy source in sub-surface utility networks due to its unique advantages. One of the primary benefits of steam is its ability to transfer energy over extended distances efficiently. Unlike liquids, steam relies on pressure rather than pumps for movement, which reduces the need for additional mechanical components and maintenance.

Steam distribution typically operates at specific pressure levels depending on its application.

- High-Pressure Steam: In district energy systems, steam is generally distributed at approximately 200 psig. This high pressure allows energy to be transported efficiently over long distances.

- Low-Pressure Steam: When steam is directly used within buildings, it is typically consumed at 15 psig. This lower pressure ensures safe and effective operation for heating and other applications.

It is essential to maintain distinct pressure levels for different parts of the system, as pressures cannot be intermixed without compromising efficiency or safety.

Maximizing Energy Savings Through Effective Steam Condensate Management

In steam systems, it is important to be cognizant of recapture of steam condensate for energy savings. As energy is consumed, steam undergoes a phase change from gas to liquid, becoming steam condensate. Like steam, condensate pressures—high-pressure (from high-pressure steam) and low-pressure (from low-pressure steam)—must not be intermixed. When condensate is fully exposed to the atmosphere, it transitions to liquid and is typically pumped for reuse. Recapturing both steam condensate and pumped liquid condensate plays a significant role in conserving energy, reducing waste, and improving system efficiency.

RPA Engineering’s Advanced Analysis

By incorporating advanced techniques like pipe stress analysis and hydraulic modeling, these networks can be optimized for safety, reliability, and performance. The integration of these analyses contributes to significant energy savings by ensuring that systems operate efficiently, minimizing energy losses, and extending the lifespan of infrastructure.

Using an integrated engineering approach—combining the expertise of mechanical and structural engineers—ensures that every aspect of the network is carefully designed and aligned with broader operational goals. This holistic strategy not only enhances system functionality but also supports sustainability and cost-effectiveness, making sub-surface utility networks a cornerstone of modern infrastructure.

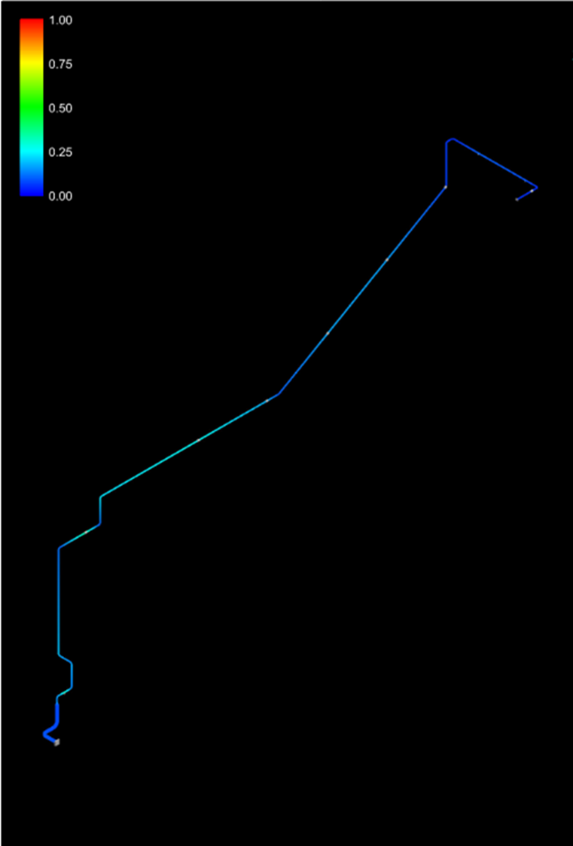

Pipe Stress Analysis in Sub-Surface Utility Networks

Pipe stress analysis is a critical process in the design and operation of sub-surface utility networks, particularly for high-energy piping systems such as steam. High-energy systems operate under significant pressure and temperature conditions, which can cause pipes to expand, contract, or experience stress over time. Proper analysis ensures that these systems remain safe, reliable, and functional under varying operational conditions.

Pipe stress analysis is a critical process in the design and operation of sub-surface utility networks, particularly for high-energy piping systems such as steam. High-energy systems operate under significant pressure and temperature conditions, which can cause pipes to expand, contract, or experience stress over time. Proper analysis ensures that these systems remain safe, reliable, and functional under varying operational conditions.

This analysis enables mechanical engineers to strategically place anchors, expansion loops, or expansion joints within the piping network. Anchors hold pipes securely in place. Since expansion increases with straight lengths of piping; anchors break up the distance, reduces the pipe stress and directs expansion outward in each direction from the anchor point. Expansion loops and joints, on the other hand, allow for controlled movement and thermal expansion. The designer must carefully select the placement of each to mitigate the risk of excessive stress or material fatigue.

Pipe stress analysis also assists the structural engineer in designing robust piping supports. Properly engineered supports ensure that the pipe’s weight, thermal expansion forces, and operational loads are adequately managed. By collaborating with the mechanical engineer, the structural engineer can create support systems that maintain alignment, reduce vibration, and prevent damage to both the piping and surrounding infrastructure. Together, these efforts ensure the longevity and reliability of sub-surface utility networks.

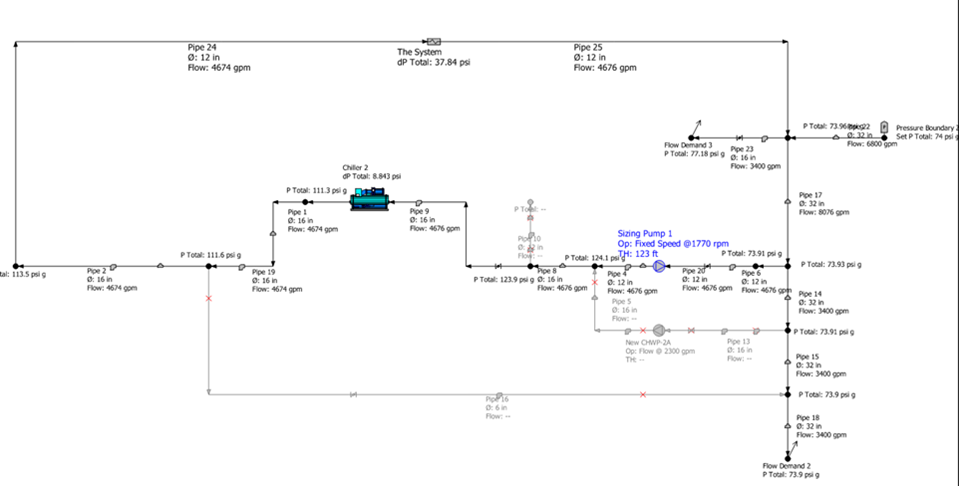

Hydraulic Analysis in Sub-Surface Utility Networks

Hydraulic analysis plays a crucial role in the design and optimization of sub-surface utility networks. This process involves creating a detailed model of the piping system and associated equipment, such as pumps, valves, and heat exchangers. By simulating the flow of fluids through the network, hydraulic analysis provides critical insights into how the system will perform under various operating conditions.

Additionally, hydraulic analysis enables engineers to evaluate different equipment options and configurations within the network. By simulating the performance of various pumps, valves, and other components, engineers can select the most effective and cost-efficient solutions for the system’s specific requirements. This approach ensures that the network is not only optimized for current needs but also adaptable to future demands, making hydraulic analysis integral to effective sub-surface utility network design and operation.

Expertise You Can Trust

RPA Engineering brings unparalleled value to sub-surface utility network projects through our specialized expertise and integrated engineering approach. The design and optimization of these networks demand advanced analysis, from precise mechanical and piping systems to robust structural engineering solutions. With all these capabilities housed under one roof, RPA Engineering ensures seamless coordination across disciplines, eliminating inefficiencies and delivering cohesive, high-performing systems.

Backed by years of experience handling complex engineering challenges, we apply our deep knowledge to tackle even the most intricate projects with precision and innovation. Our proven track record of success in sub-surface utility network design highlights a commitment to quality, reliability, and energy-efficient solutions, making RPA Engineering a trusted partner for critical infrastructure projects.

Paul Parise, PE, LEED AP BD+C

Paul J. Parise is Vice President of Pittsburgh Operations for RPA Engineering.