If you ever watched “The Jetsons,” the 1960s cartoon series take on a space age family in the 21st century, you saw things like robotic toothbrushes, a robotic vaccum cleaner, a home computer, a microwave oven, cellphones and the family robot Rosey.

What you didn’t realize that some of these robotics were early versions of collaborative robots, the kind of robots designed to work around people.

Fast-forward in real time to the 21st century. Those cartoon images were a precursor to a global industry predicted by 2025 to generate revenue worth $147.26 billion, fueled by an compound annual growth rate of 17.4 percent, according to Transparency Market Research, a business intelligence company in Albany, N.Y., whose clients include Fortune 500 companies.

The service robotics market in North America is expected to reach $8.6 billion by 2022, with a compound annual growth rate of more than 17 percent, according to Global Market Insights Inc., of Selbyville, Del.

“We’re just beginning to approach ‘The Jetsons,’ ” said Richard P. Aulenbach Jr., president and CEO of RPA Engineering, Wyomissing, which recently launched its Robotics and Innovation division.

Aulenbach founded the firm in 1989. It offers comprehensive mechanical, electrical, automation and structural analysis services for the pharmaceutical/biotech, industrial, power and utility industries, and for university and health care markets. The firm has five locations and 100 employees.

Its client list includes Carpenter Technology Corp., PPL, Exide, Alcoa, Quest Diagnostics, Johnson and Johnson and the University of Pittsburgh Medical Center.

Collaborative robotics and innovation

“A collaborative robot is any device that can move itself or things on its own and perform a function,” Aulenbach said. “For example, there are vacuum robots and robots that can even cut your lawn.”

Five robotic projects in the last six years led to the formation of the Robotics and Innovation division, which Aulenbach heads. Currently, the division is involved in biomedical device projects as well as alternate hyperloop transportation design, and a reduced pressure tube-based inter- and intra-city transportation system for passengers and cargo, introduced by Elon Musk, of Tesla electric car fame.

“The division is the culmination of these recent efforts and our desire to continue bringing innovative design solutions to our clients,” said Aulenbach. “We bring to the marketplace robots developed with software and algorithms programmed to make movement so that the robot interfaces with the work it’s doing.”

Echoing Transparency Market Research’s projections, Aulenbach said he believes that robotics as an industry has a huge, huge future in all aspects and health care in particular.

“As our population has evolved, we’ve become less inclined to do risks in severe, dangerous environments,” he continued. “Robotics help to minimize those dangers while saving mankind at the same time.”

Aulenbach points to firefighting as one of the potential applications for robotics.

“On the ground or with a drone, firefighters will be able to locate a person trapped in a burning building,” he said.

He also said that collaborative robotics can be applied to repetitive or menial tasks to help increase efficiency in large as well as small to midsized companies while freeing up a person to work on more complicated aspects of a project.

Aulenbach emphasized that robotic technology is not meant to take away jobs.

“It’s most useful in difficult environments,” he said. “It’s intended to help the workforce, not replace it.”

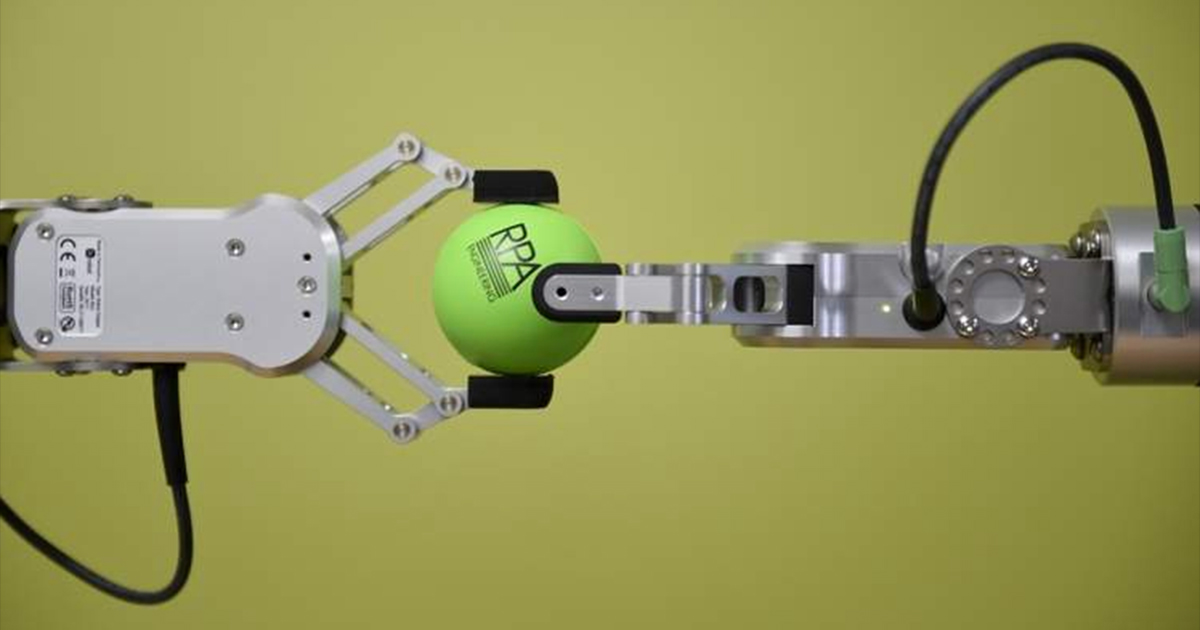

At the Delaware Valley Chapter of the International Society for Pharmaceutical Engineering’s 28th Annual Symposium and Exposition, held Feb. 1 at Lincoln Financial Field, Philadelphia, RPA previewed a robotic collaborative device manufactured by Universal Robots of Odense, Denmark, for which RPA programmed a pick and place activity that uses parent logic.

“We got the components ‘talking’ to each other,” said RPA project manager Jon Becker of the device’s two robotic arms, one of which is referred to as the parent, the other the child. The arms are designed to mimic the range of motion of the human arm. The demonstration involved picking up tennis balls and placing them in a specified location.

Becker said that the robots are controlled by a laptop driver, which provides an interface screen that an operator uses to monitor the activity of the robots through the entire “pick and place” sequence. In the event that a person working side by side with the robot comes too close to the sequence, sensors automatically will interrupt and shut down the activity, thus ensuring safety.

“It’s called unspecified resistance that stops the robot,” added Aulenbach.

RPA works with many of its clients on a sole source basis. The reason for such a coveted relationship, according to Aulenbach, is that “it takes so much knowledge of the specifics of their application needs, ranging from the very basic to the very complex.”

Tapping for the future

Robert Aldinger, 34, a robotics specialist at RPA, commented that there are future applications for robotics to work with people in close collaboration, pointing to the pharmaceutical industry, where robots are beginning to make inroads.

Aldinger always has been fascinated by electronics and mechanics.

“Robotics brings both worlds together,” he said. “It simplifies process design in general by using fewer moving parts than a machine; is efficient and reliable.”

Will Hood, 25, a colleague of Aldinger, said that “robotics can be brought into a process without isolation working hand in hand with an operator. Robotics opens the door to endless possibilities.”

Hood says that as a child, he was always curious about how things worked. Robotics back then were presented as science fiction.

“Growing up, they were futuristic,” he said. “Now, they’re real, and R2D2 (a “Star Wars” robot) was absolutely a collaborative robot.”

Aldinger and Hood were on their way to Pittsburgh to set up the preliminary phases of a robotic competition at the University of Pittsburgh.

“These competitions challenge students to think out of the box,” said Hood, “and to think from the ground up.”

Aldinger stated that teachers as well as parents should encourage students who have an interest in robotics and technology.

“It’s critical,” he said of the learning process. “Schools are incubators for innovation and open minds to new possibilities.”

In addition to the University of Pittsburgh, RPA maintains affiliations with Lehigh, Penn State, Widener, Carnegie Melon, Bucknell and Virginia Tech as part of its recruiting initiative for employees.

“There’s a huge population of technology that is rich in talent,” Aulenbach said, “and we want to capitalize on it.”

RPA also runs an internship program for students in the Berks County region.

Elroy Jetson, the futuristic family’s genius child, better watch out.