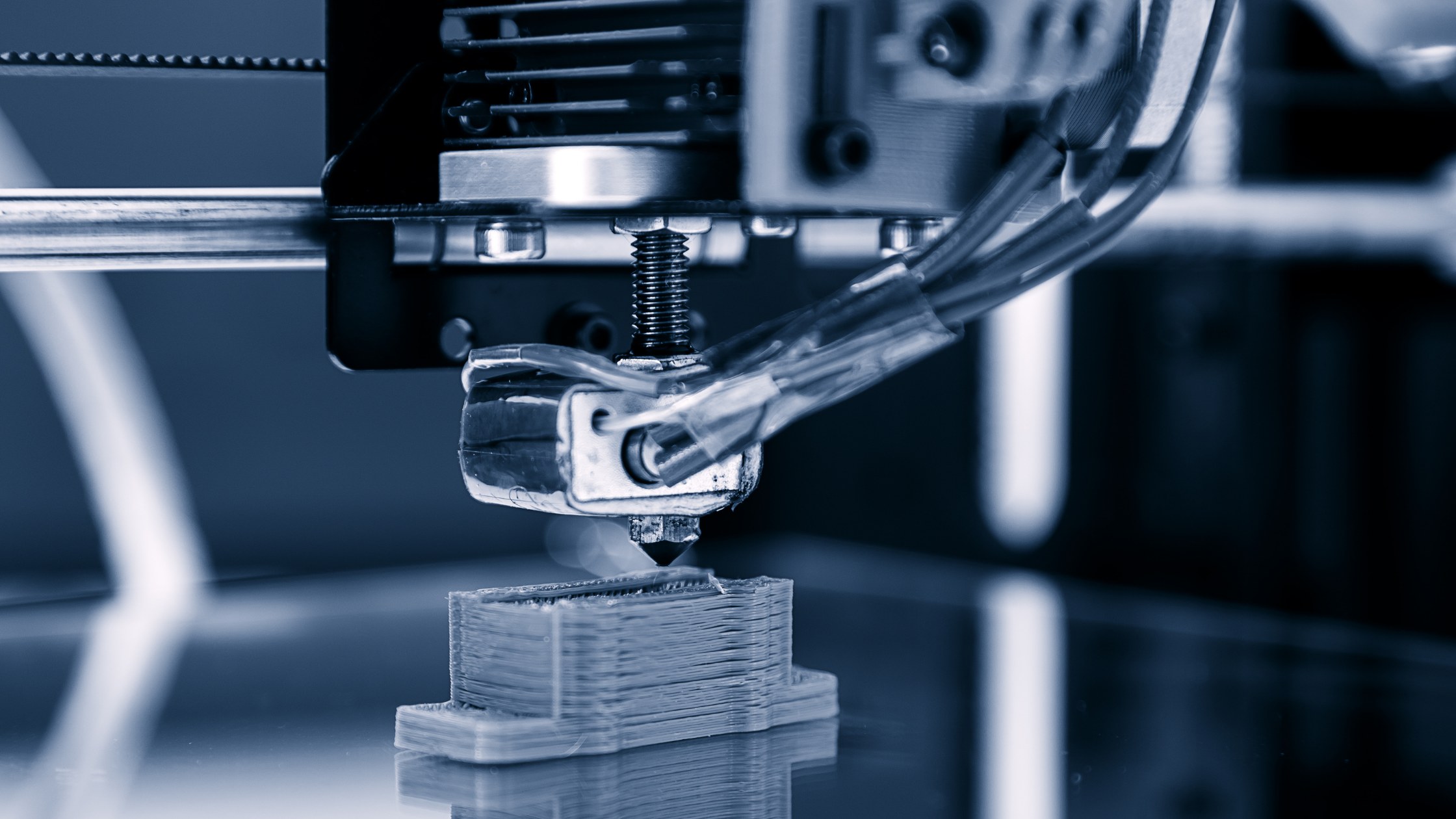

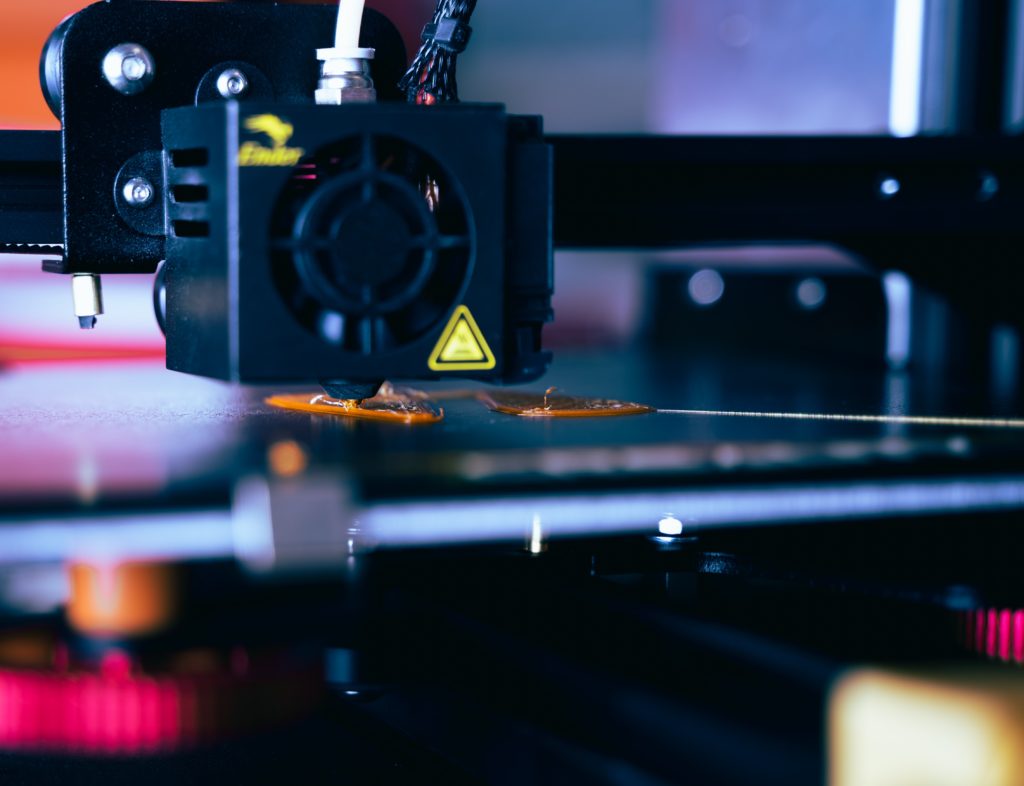

The first 3D printer was developed in the mid-1980’s by Charles W. Hull. At the time, the technology was revolutionary. Taking something simple such as a drawing and being able to model it into something that could be printed in 3D changed the way we design things. Over time, the technology has grown and continues to become more advanced. Today, 3D printers are not just seen in big commercial industries. They can be seen in colleges, small business, and even at people homes. The current price range for 3D printers can range from $200 to well over $100,000. They have become easier to use and compatible with many different types of systems, allowing for a high versatility. Originally, and today, most simple 3D printers use certain types of plastic to print things. But more expensive printers use other materials and have the capacity to print all sorts of things. With this is mind, we ask ourselves, what can 3D printing technology really do?

3D printing technology currently and will continue to create huge opportunities for the medical industry. According to a recent analysis, the market for medical 3D printing is estimated to be valued at approximately $1.25 billion. This number is expected to grow, reaching upwards of $6 billion within the next decade. 3D printing technology is currently used is multiple different branches of healthcare, and over time, this number will continue to expand.

One of the biggest specialties that benefits from 3D printing is Orthopedics. Dealing with the body’s musculoskeletal system, orthopedic medicine involves bones, joints, ligaments, muscles, and nerves. This complex system is what allows us to move and work. Since we rely on this system so much, it is quite common to have issues such as a broken bone, or a torn muscle. In some cases, people can even be born with a missing joint. Often, when these issues arise, surgery is required. Orthopedic surgery often utilizes what are known as orthopedic implants, medical devices used to replace a missing joint or bone. 3D printing technology can be used to make these implants, producing more enhanced and more flexible devices. Due to the design flexibility, these implants can be designed for very specific purposes. For example, by utilizing 3D printing technology, a doctor can create an implant with a porous surface structure, facilitating quicker integration between an artificial implant and a currently living bone. The ability to make patient specific implants with enhanced design and specific purpose is why orthopedic medicine has shot towards the front of specific medical branches that can utilize the potential of 3D printing.

Personalized surgery is another medical branch is increasingly utilizing 3D printing technology. Before any surgery, it is critical that a unique, detailed plan be developed for the patient. Since every patient is different, it is important that everyone involved is on the same page. By starting with a CT or an MRI scan, a digital model can be created, and 3D printed, creating a detailed, high-accuracy 3D model that can be used to assist in pre-surgical planning. This can help reduce the time a patient spends in an operating room, and ultimately help lead to fewer complications. While performing surgery, it is also critical that the right tools be used. This is another area that utilizes 3D printing technology. Doctors can 3D print personalized surgical tools from forceps to scalpel handles, and even clamps. These personalized tools can help increase dexterity and make an overall surgery easier for all those involved.

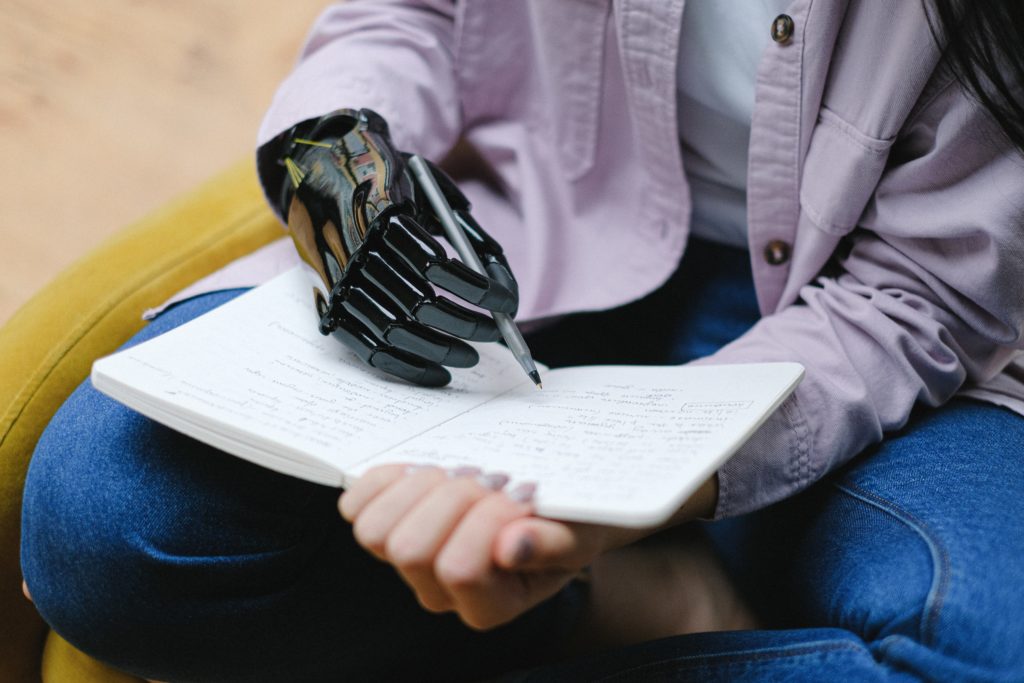

The market for 3D printed medical devices like prosthetics, braces, dentures, etc. is also growing at an exponential rate. It is expected to be valued at around $2.3 billion by the year 2025. 3D printed medical devise allow for low-cost personalization, allowing healthcare professionals to create a custom device for the unique needs of their patients. Traditional manufacturing methods like mold casting require special tooling and take a long time to produce. With 3D printing, prosthetics can be created in a fraction of the time that it would normally take to make. 3D printing also allows them to be tailored to the patient’s anatomy, improving the fit of the prosthetic. This is becoming especially common in children. Children grow rapidly, meaning they might grow out of there prostheses, needing new replacements with a larger size version. The speeds and cost of these 3D printed devices makes this need a much easier task. Along with prosthetics, dental 3D printing is becoming more and more common. Like other medical devices, 3D printing can provide better accuracy in things such as dentures, braces, and most commonly as we see today, clear aligners. By the year 2027, it is expected that 3D printer technology will become the leading production method for dental restorations.

As with everything, utilizing the full potential of 3D printing in healthcare does come with challenges. The main one of these being regulatory framework. The lack a full comprehensive framework for 3D printed medical devices makes it challenging for the industry. Although regulator bodies such as the FDA are working on this, it is a long process that must be analyzed and considered very carefully. What the device is to be used for, how much it is going to be used, the risk to the patients, how it will hold up over time, etc. are all things that must be considered.

Overall, it is believed that 3D printing will play a big role in the future of healthcare. In today’s healthcare, 3D printing technology allows us to aid in all sorts of things. From creating customized surgery tools, to anatomical models, to dental products, 3D printing is already heavily utilized in the medical industry. Many leading hospitals and labs are adopting 3D printing as part of their healthcare and research. As the technology becomes more advanced, the demand for 3D printing in healthcare will only grow. As these needs grows, some of the challenges that we currently face must and will be concurred. Regulatory framework will be developed, and there will be a clear idea of all the things that 3D printing can be used for in the healthcare industry. With this comes the ability to expand into other healthcare sectors such as bioprinting and pharmaceuticals. As with everything, in the future, healthcare will look a lot different then it does today. At the front of this is 3D printing technology. Although still young, 3D printing will be a key technology to help drive forward the healthcare industry. To sum it up, we look at a quote from Dr. Craig Goodmurphy, “This is complex medical engineering, and the possibilities are endless.”